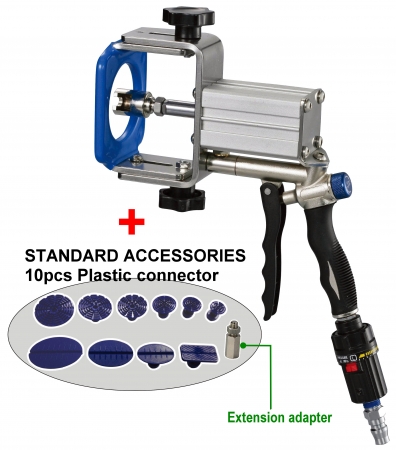

Pneumatic Puller

Model

KA-9060K

Specification:

- Air inlet: 1/4”

- Operating pressure: 3~10 bar (0.3~1MPa) (40~145Psi)

- Front of pneumatic cylinder with air vent, can be makes center shaft movement smoothly and help to cool down hotmelt glue.

Description

|

|

Pad size:

.jpg) 47 x 32mm |

.jpg) 39.1 x 26mm |

.jpg) 32 x 21.5mm |

.jpg) 31.5 x 16mm |

.jpg) 39.2mm |

.jpg) 34mm |

.jpg) 30.5mm |

.jpg) 24mm |

.jpg) 19mm |

.jpg) 14mm |

Contents:

.jpg)

Operation Steps:

Step 1: Choose the suitable pad, and put some hot glue on pad by hot glue gun.

Step 2: Use heat gun to blow the hot glue of the tab to soften the hot glue.

Step 3: Stick the pad to the small dent of the car, and use the heat gun to blow again to fix the pad and the small dent.

Step 4: Wait for 5 seconds to cool the hot glue, and try to pull the pad by hand to check the pad and the small dent are stuck.

Step 5: Connect the pneumatic small dent puller damage to the air compressor.

Step 6: Adjust the pressure control valve of the puller. Then, hook the connective hook of the puller with the pad, and make sure they are hooked.

Step 7: Adjust the two adjustable screws to make sure the height of the connective hook is suitable.

Step 8: Press the trigger of the puller until the dent is recovered.

Step 9: If it Is necessary, rotate the puller to different angles and repeat the step 8 to make sure the whole dent is recovered.

Step 10: Separate the puller and the pad, and then use the heat gun to soften the pad until the pad can be removed.

Step 11: Use the heat gun to blow the glue on the dent place, and use the plastic scraper to scrape the remaining glue. And the dent recovery is finished.

.jpg)

.jpg)

- 1pc Pneumatic Small Dent Damage Puller.

- 10pcs Glue pads.

- 1pc Extension Adapter.

.jpg)

Operation Steps:

Step 1: Choose the suitable pad, and put some hot glue on pad by hot glue gun.

Step 2: Use heat gun to blow the hot glue of the tab to soften the hot glue.

Step 3: Stick the pad to the small dent of the car, and use the heat gun to blow again to fix the pad and the small dent.

Step 4: Wait for 5 seconds to cool the hot glue, and try to pull the pad by hand to check the pad and the small dent are stuck.

Step 5: Connect the pneumatic small dent puller damage to the air compressor.

Step 6: Adjust the pressure control valve of the puller. Then, hook the connective hook of the puller with the pad, and make sure they are hooked.

Step 7: Adjust the two adjustable screws to make sure the height of the connective hook is suitable.

Step 8: Press the trigger of the puller until the dent is recovered.

Step 9: If it Is necessary, rotate the puller to different angles and repeat the step 8 to make sure the whole dent is recovered.

Step 10: Separate the puller and the pad, and then use the heat gun to soften the pad until the pad can be removed.

Step 11: Use the heat gun to blow the glue on the dent place, and use the plastic scraper to scrape the remaining glue. And the dent recovery is finished.

.jpg)

.jpg)